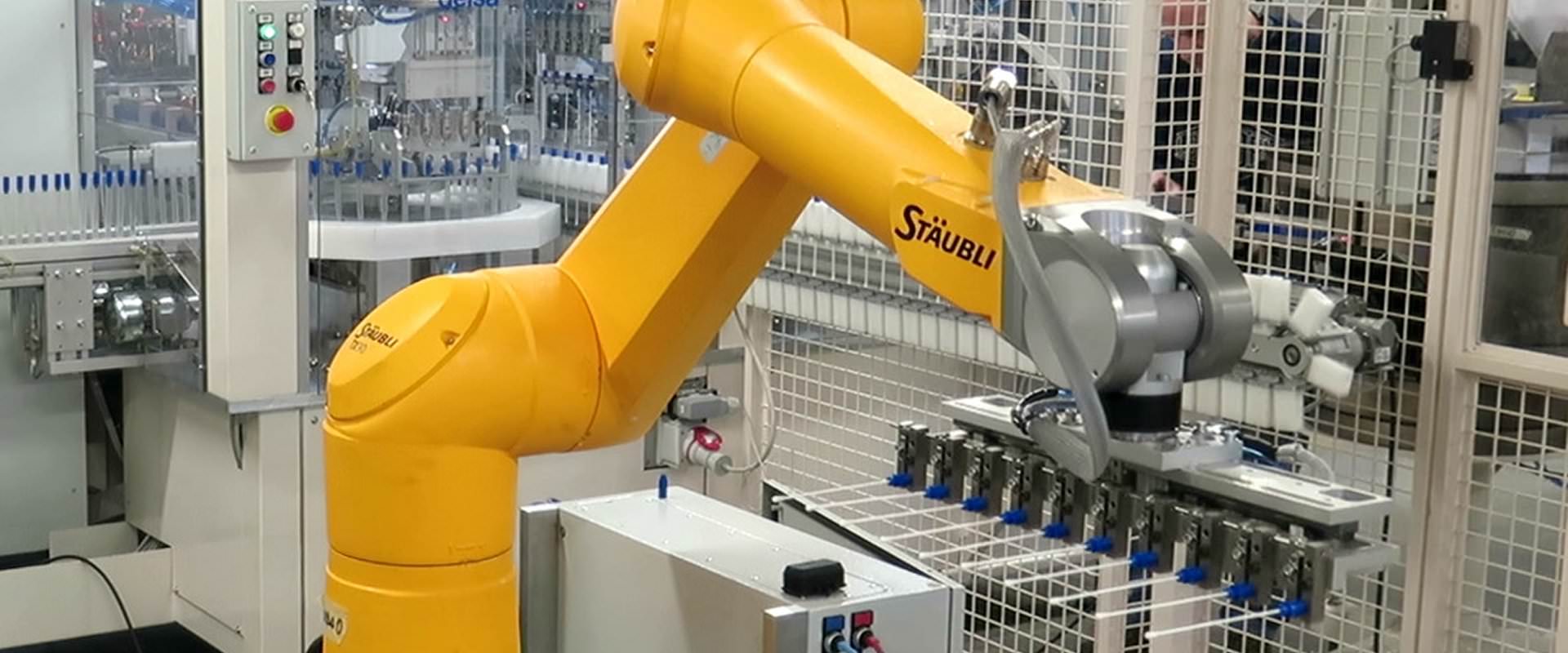

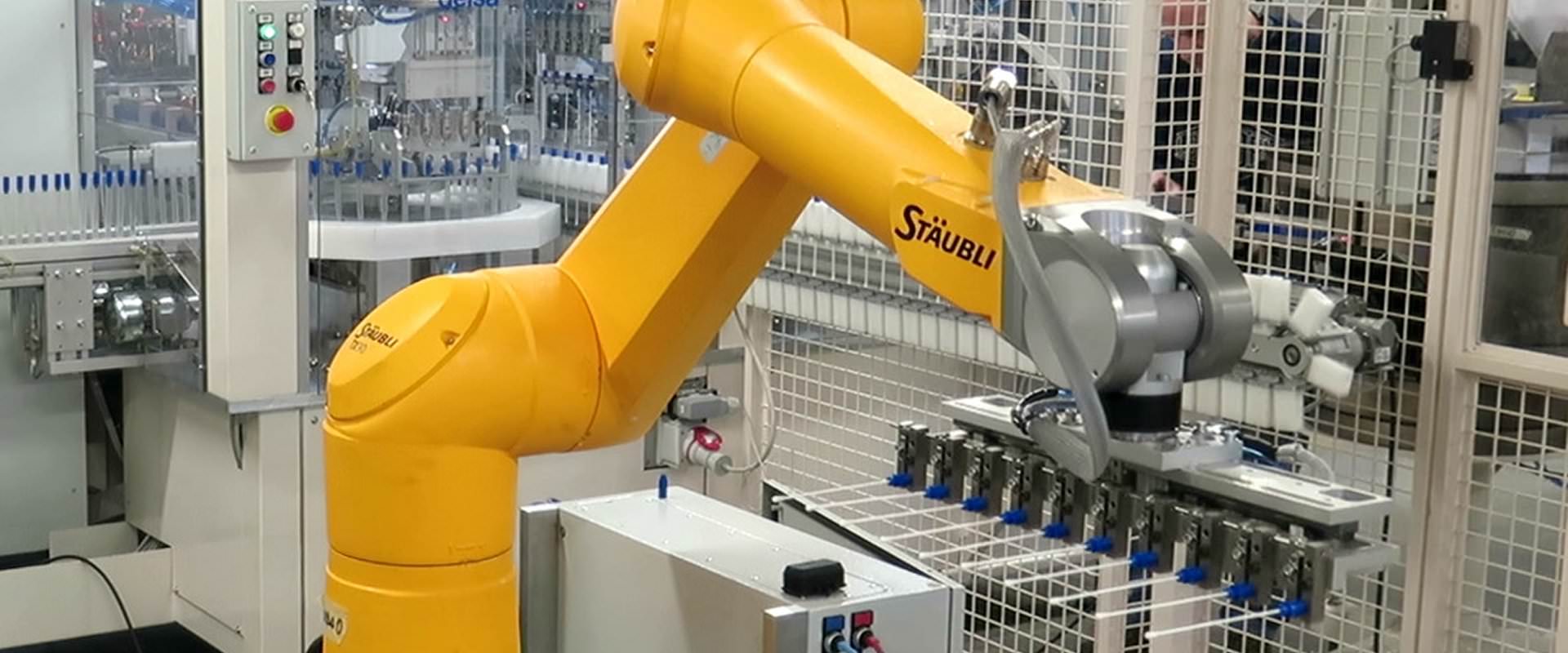

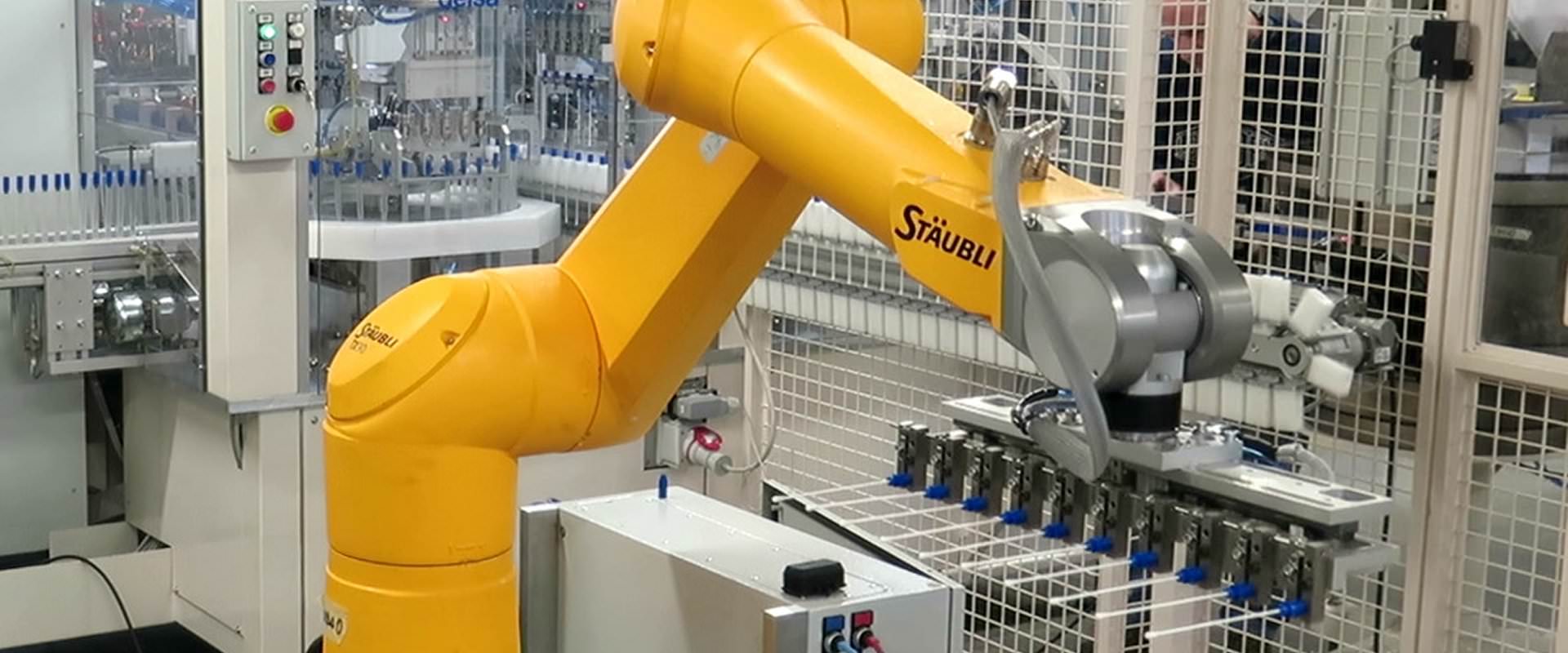

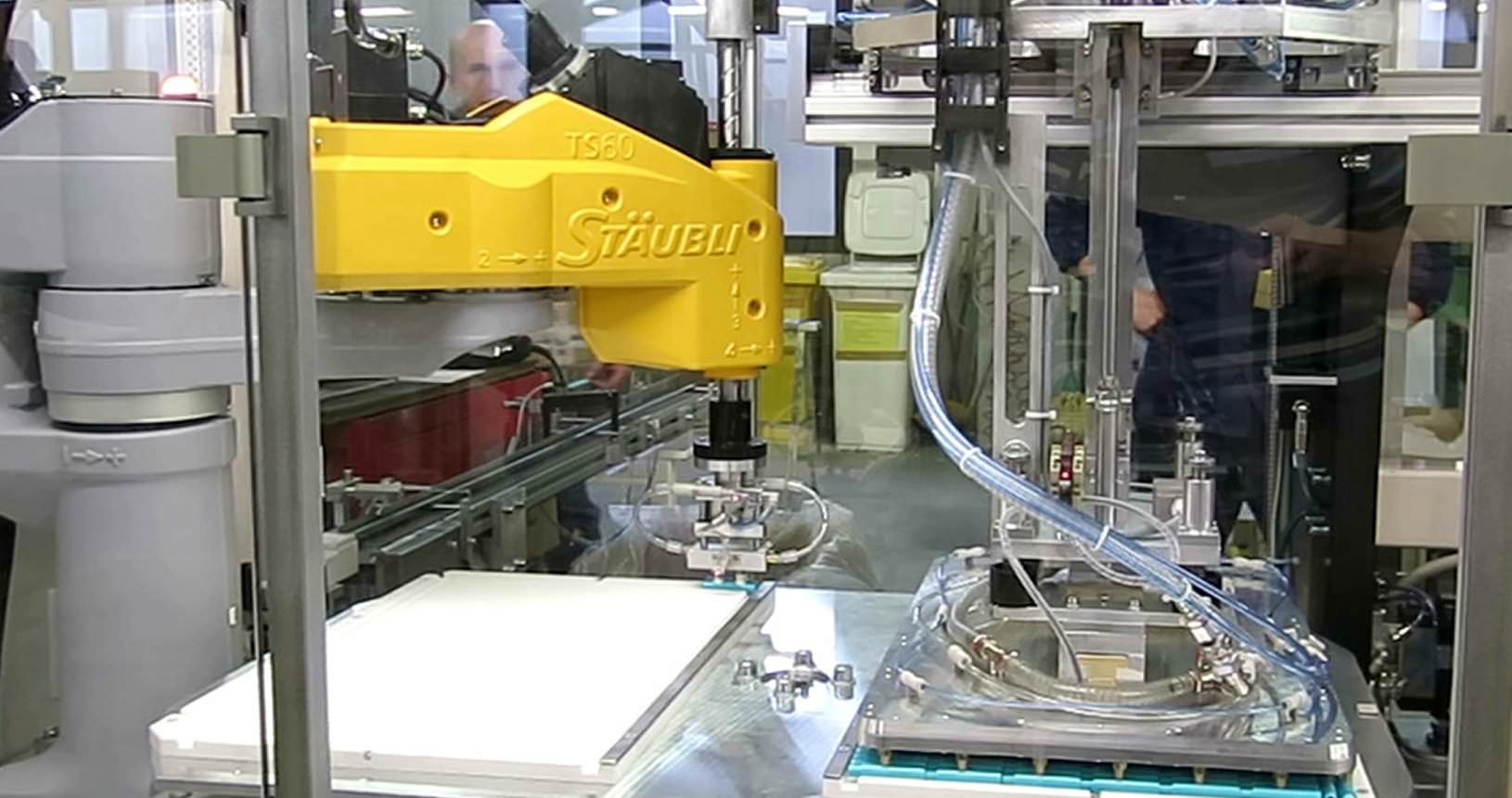

Here are some examples of machines designed and built by delsa:

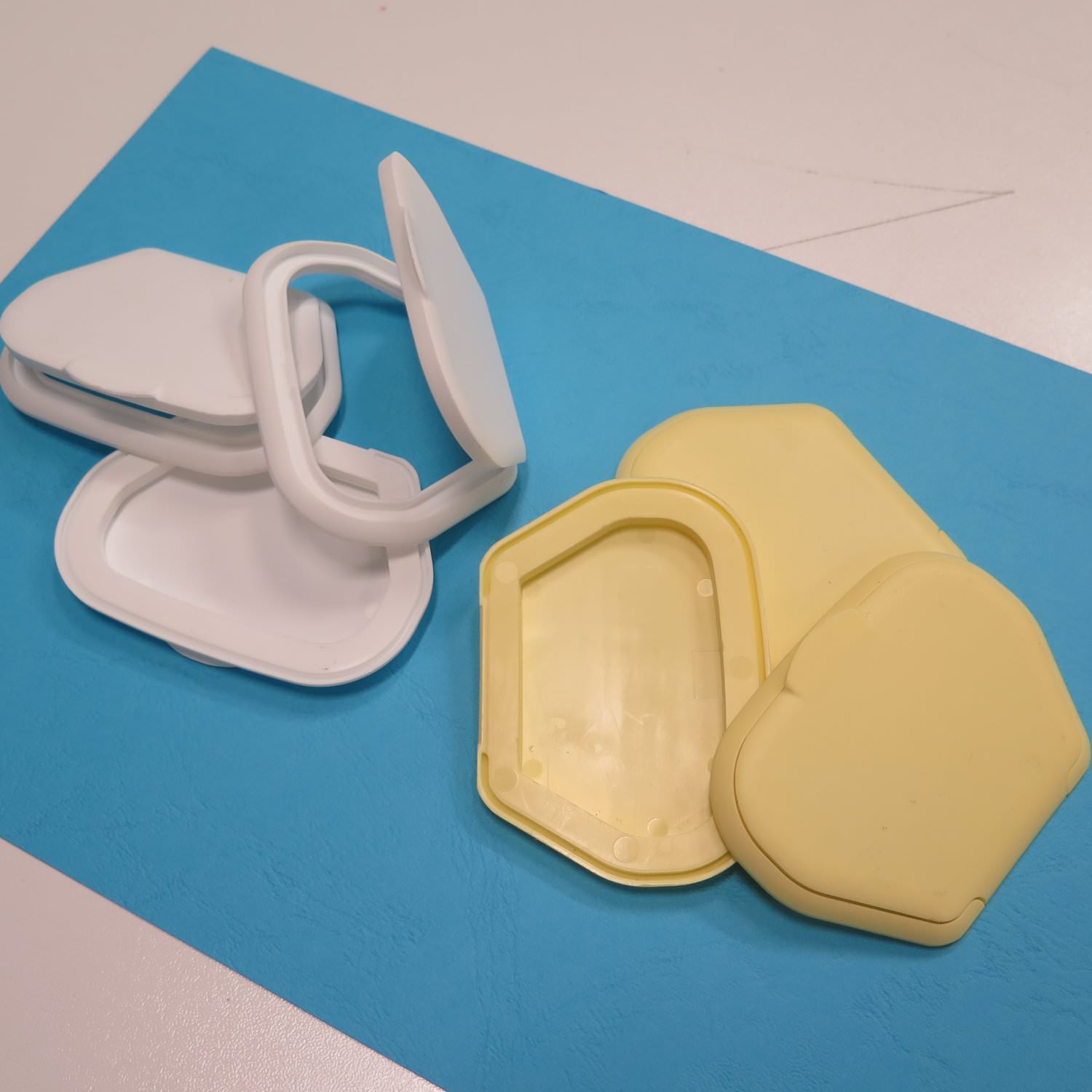

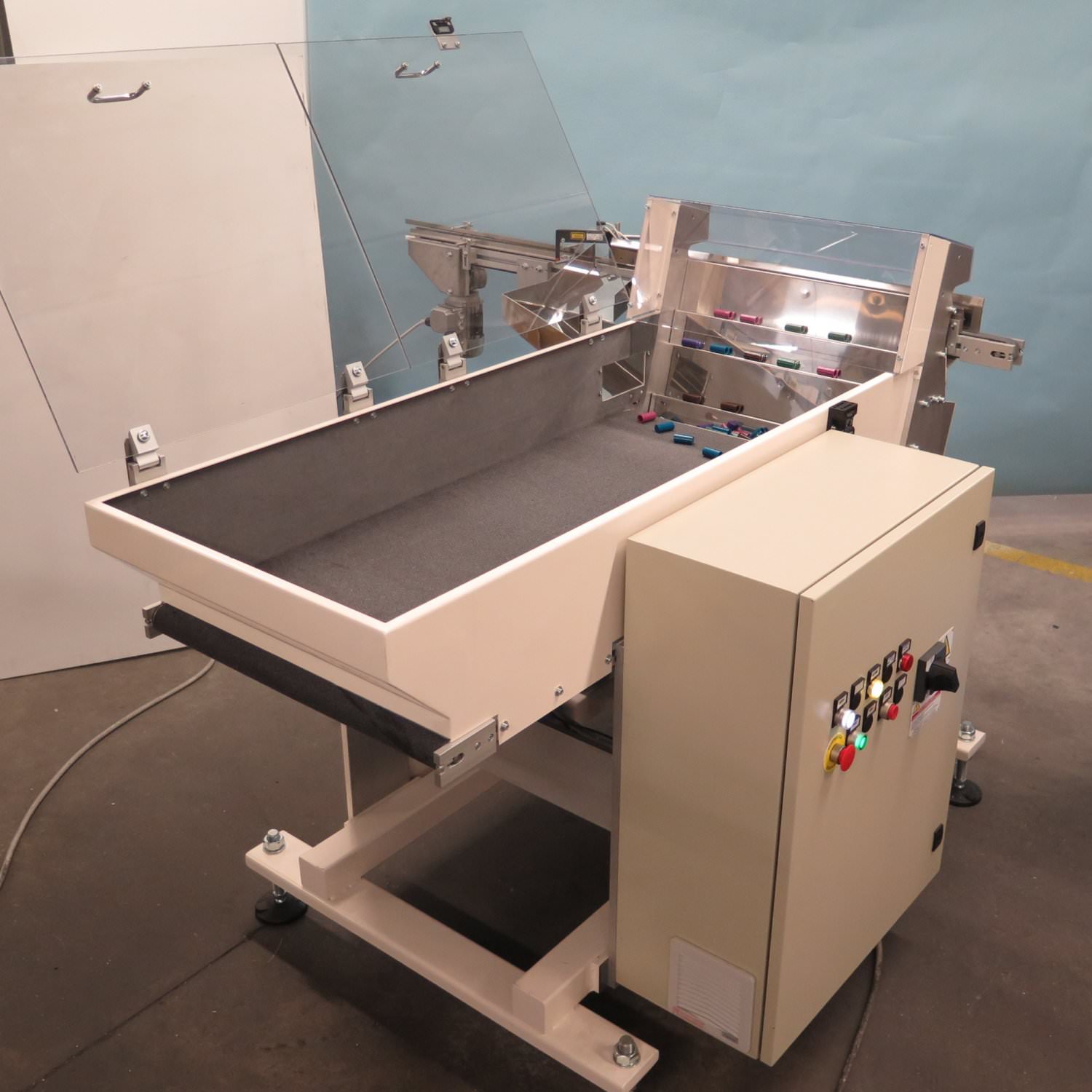

• depalletisers able to take the pieces from trays or boxes and then deposit them on a conveyor belt. Picking can be carried out by 4/6 axis robots or by manipulators operated by electric or pneumatic actuators;

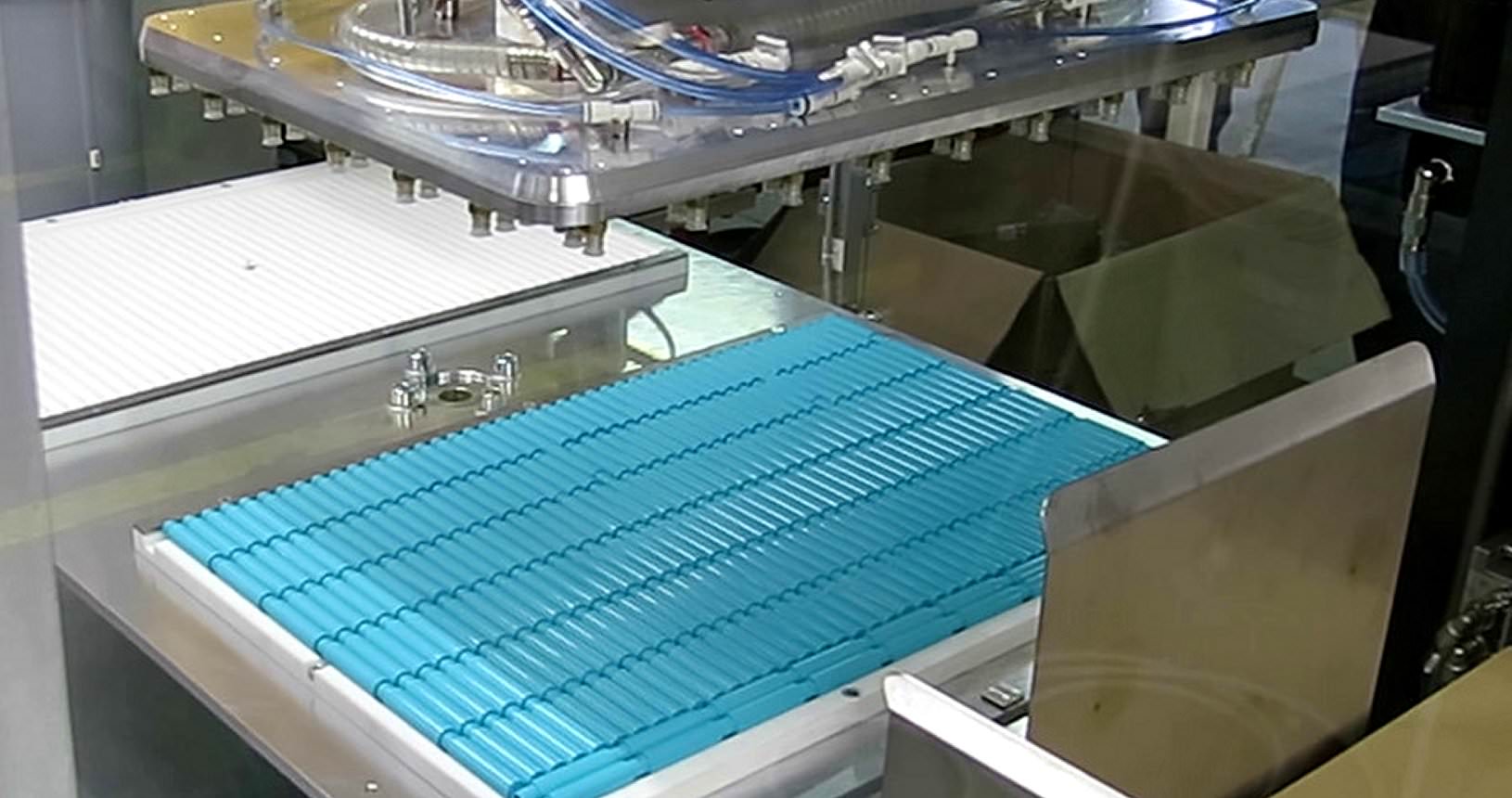

• palletisers to perform the reverse operation, neatly placing the pieces on trays or in boxes;

• special systems for automatic lines loading, such as painting or metallisation lines.