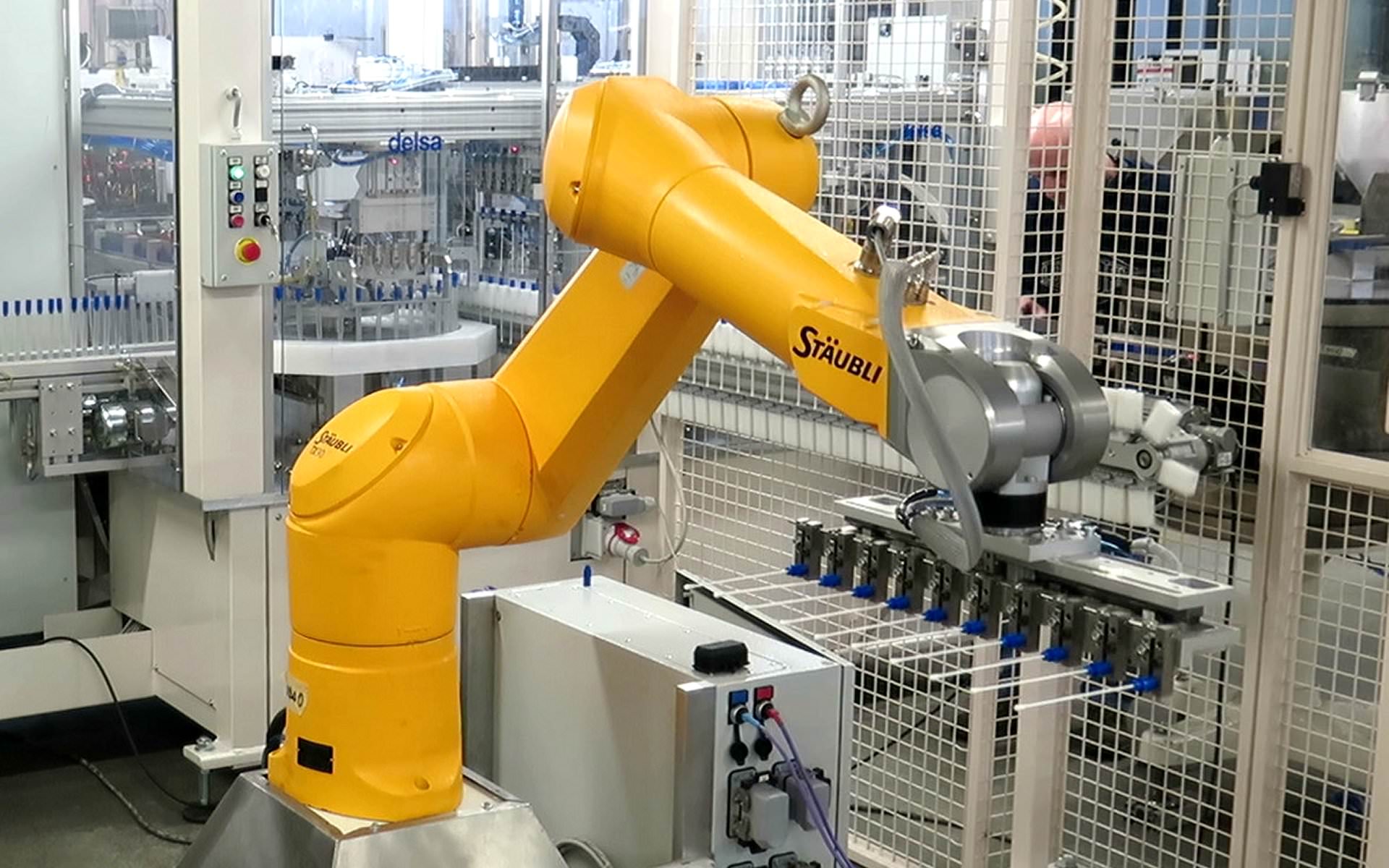

delsa is a small company operating in the industrial automation sector. Since 1982 it has been producing hot stamping and assembly machines and providing industrial automation solutions, especially dedicated to the packaging and plastic material items fields.

Since 2014 its offer has been enlarged with the addition of pad printing machines, through the acquisition of the Tampograf brand.

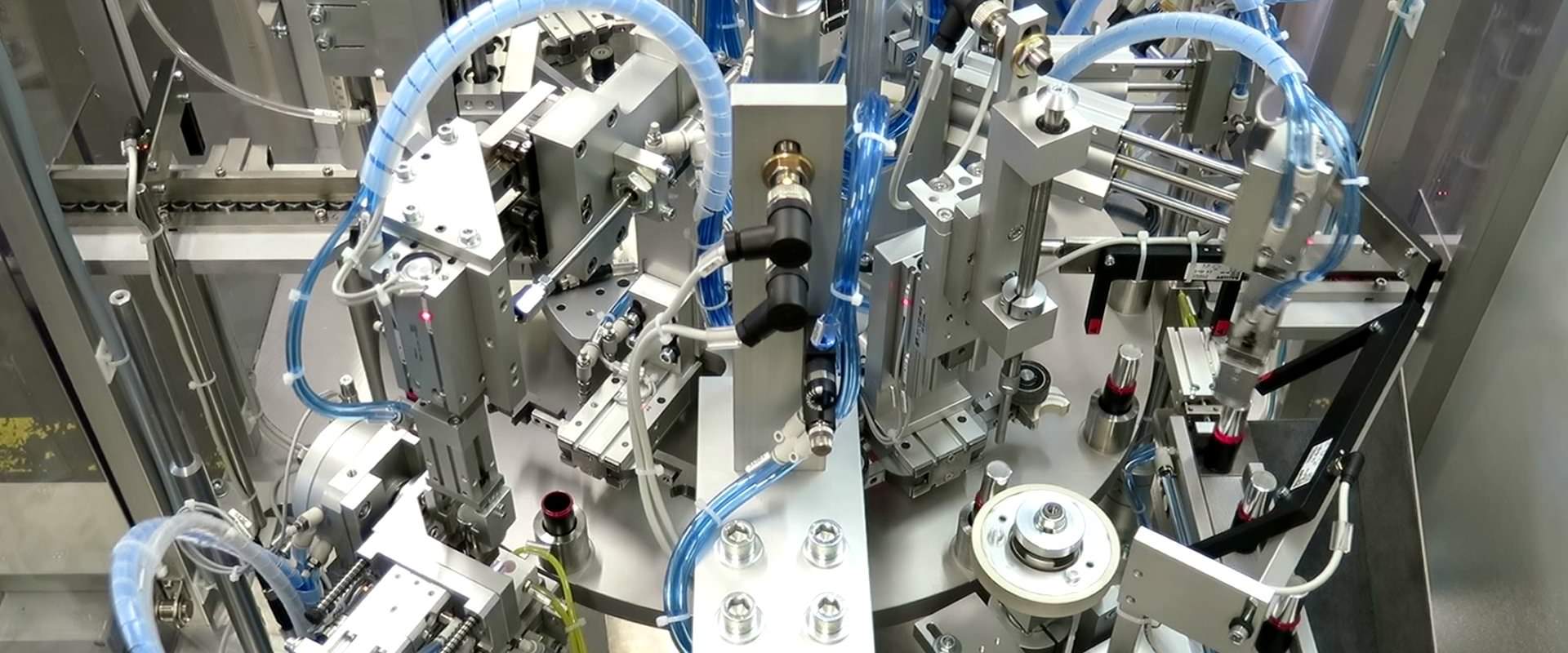

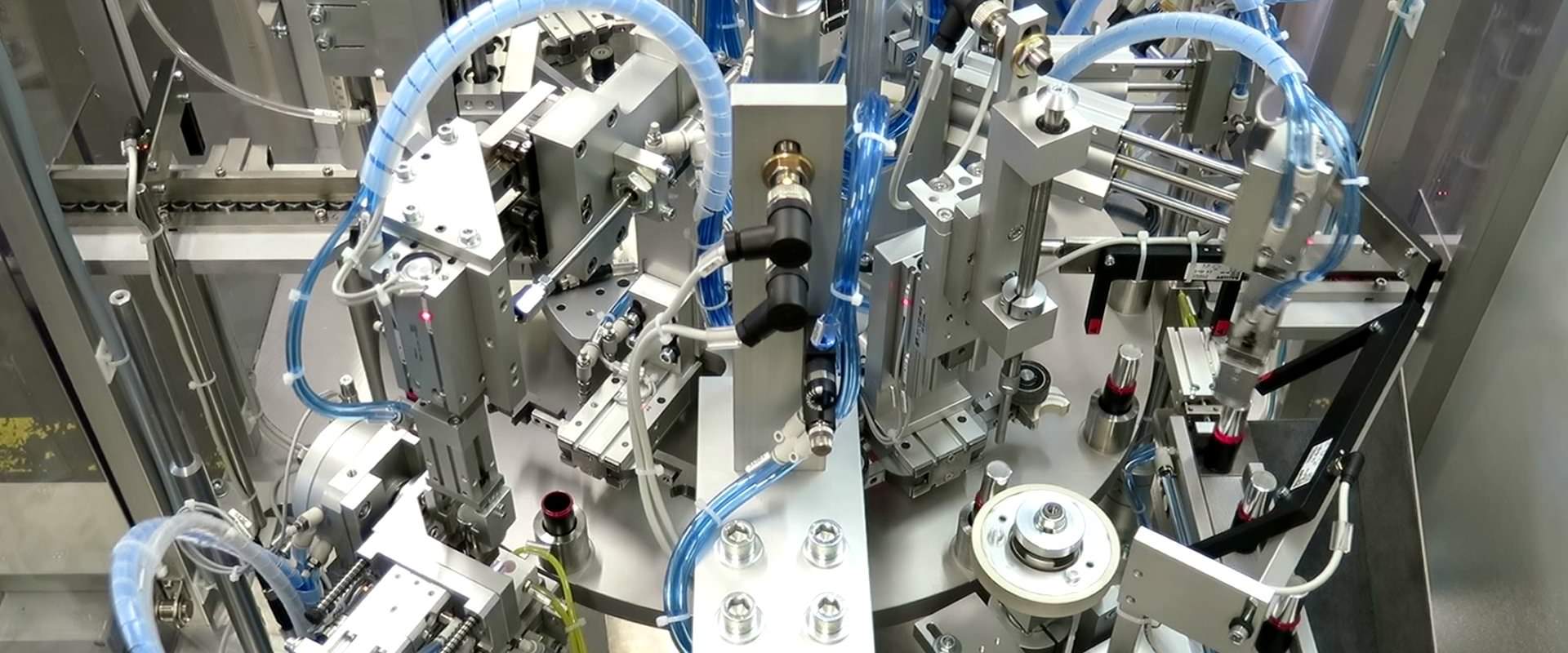

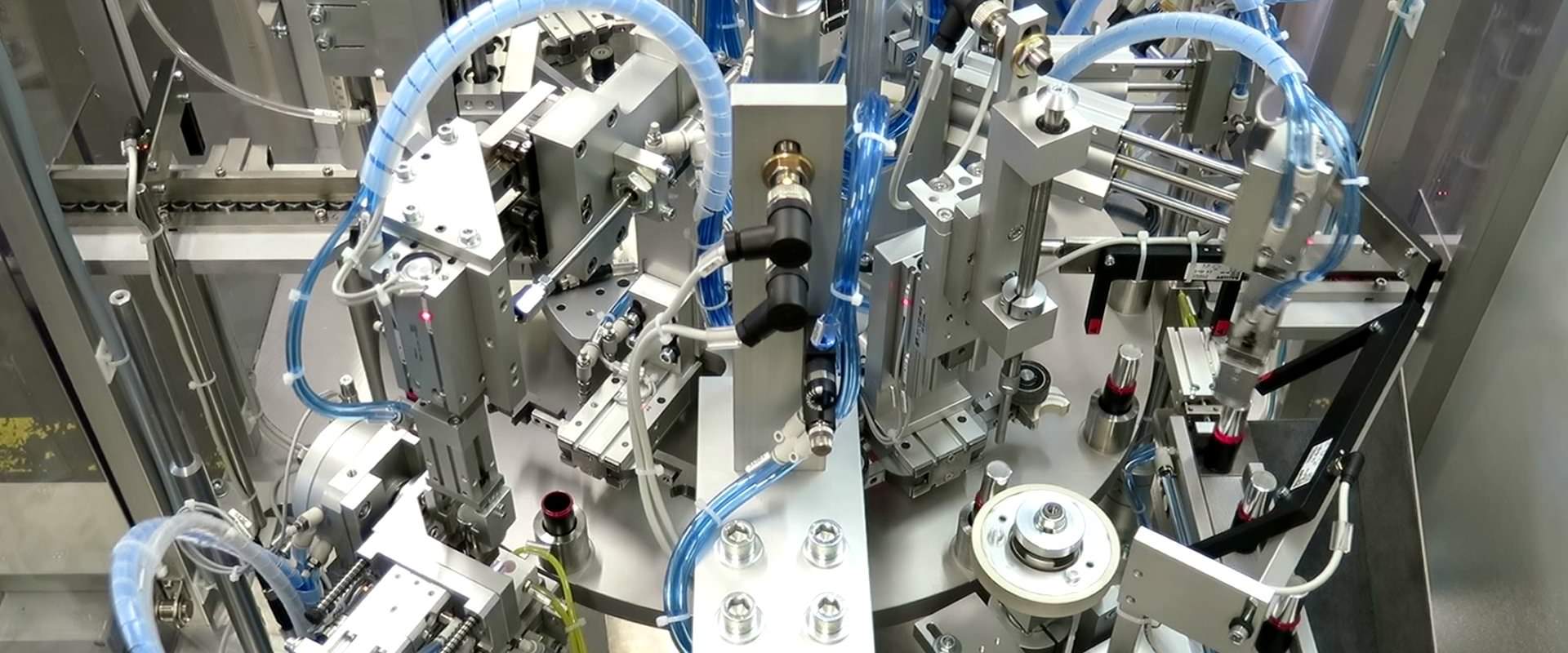

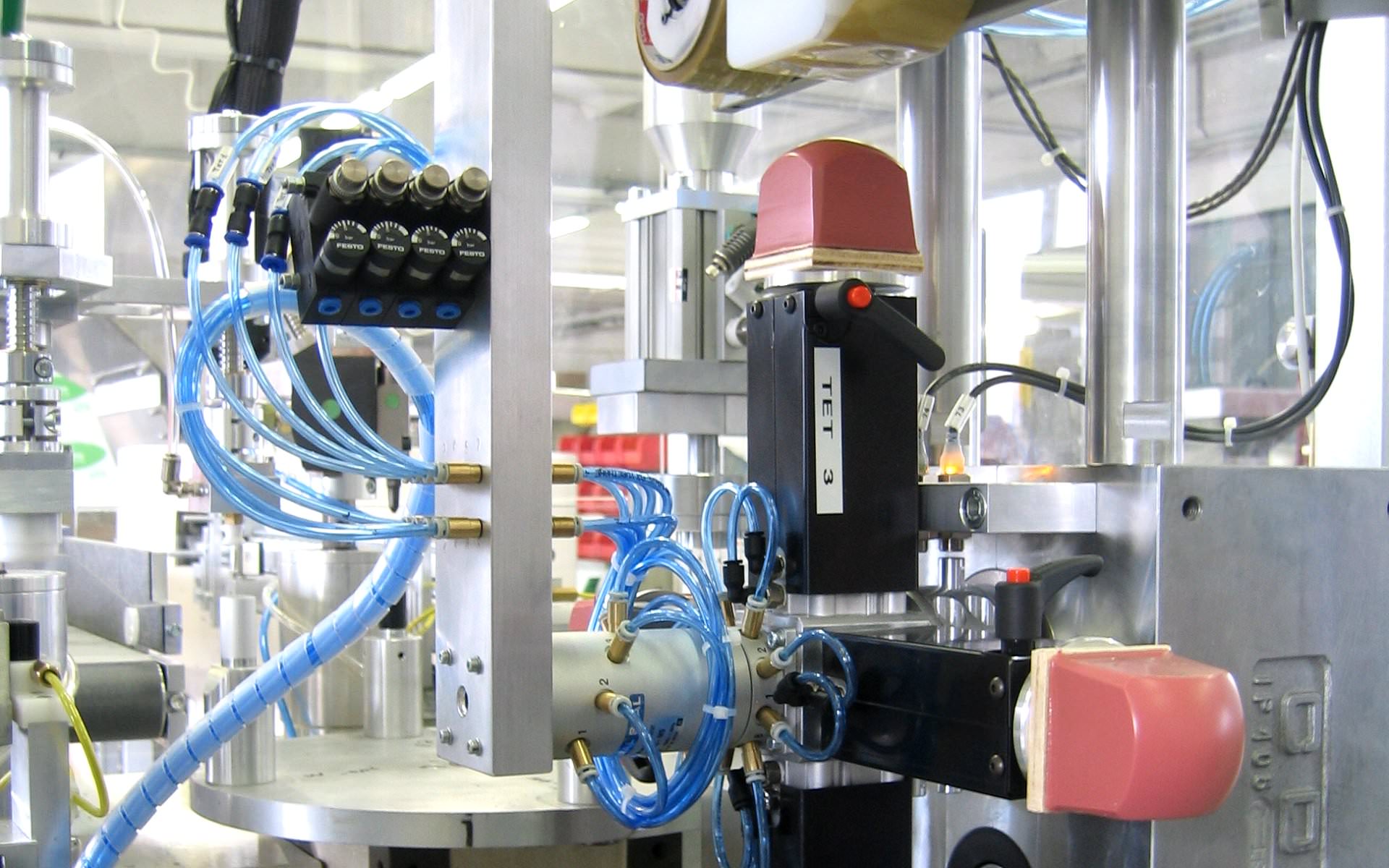

Every phase of the machinery construction is carried out within the company, from mechanical and electrical design to final assembly.

Since 2004 delsa also offers the machining service on behalf of third parties.

The plant is based in Grantola, in Varese, Lombardy, in a 3,250 sqm building: 20 workers are employed , coordinated by the owner, Dante Dellea. In almost 40 years of activity, delsa has sold more than 1500 special machines distributed in more than 20 countries all over the world. The reference fairs in which delsa participates are PLAST in Milan and Cosmoprof in Bologna.