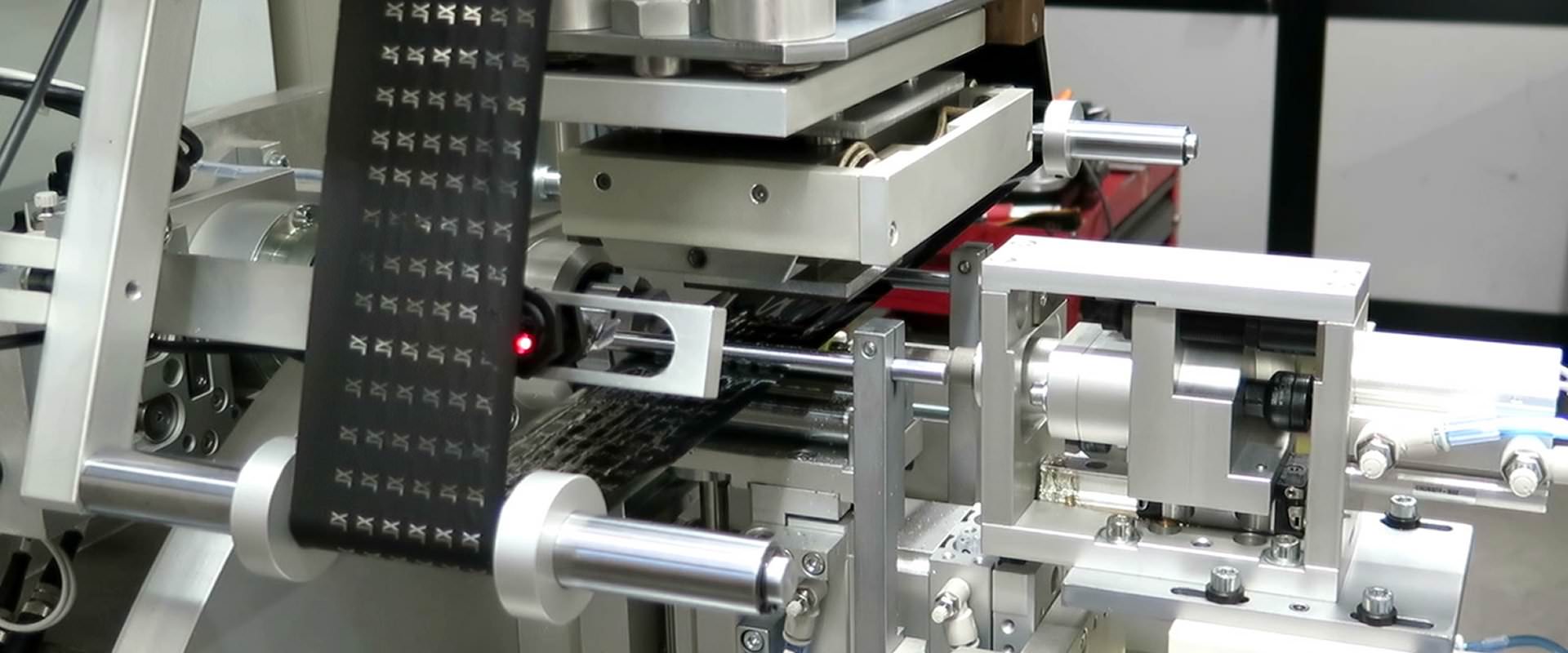

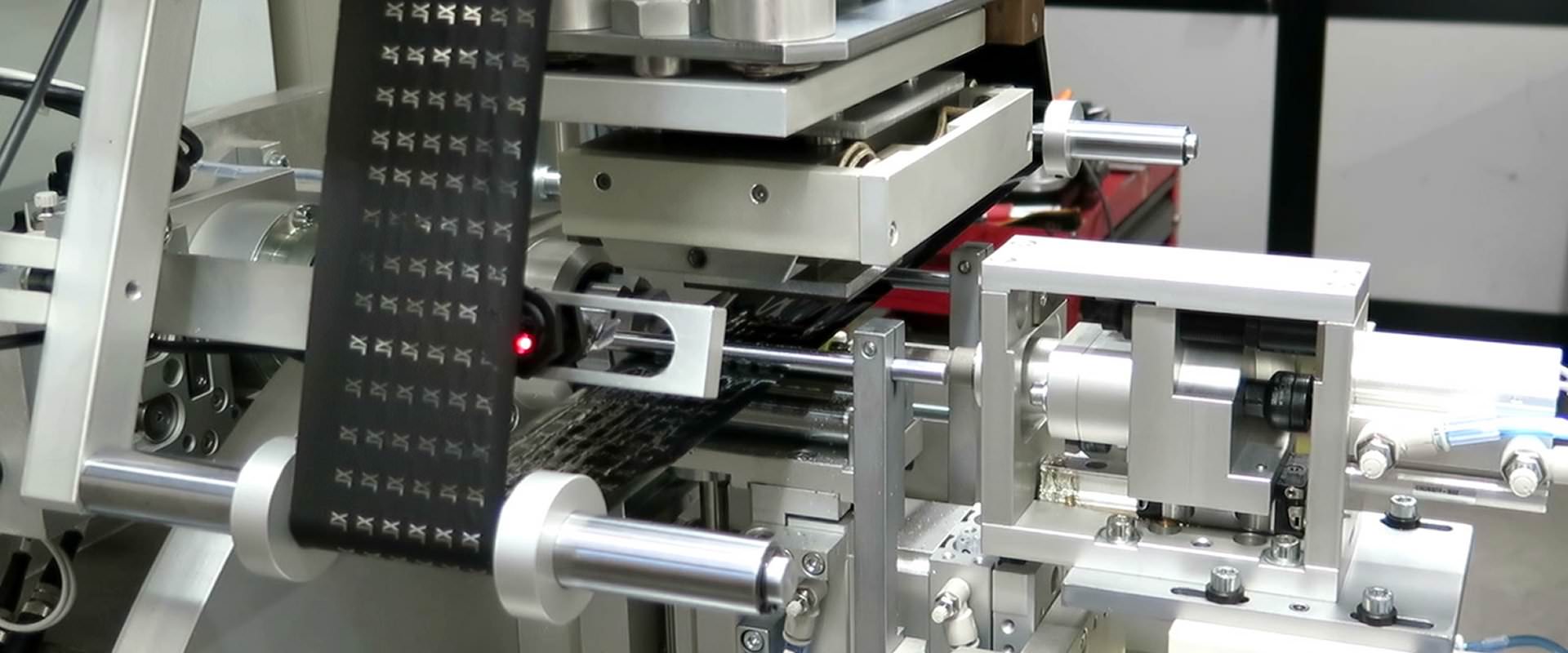

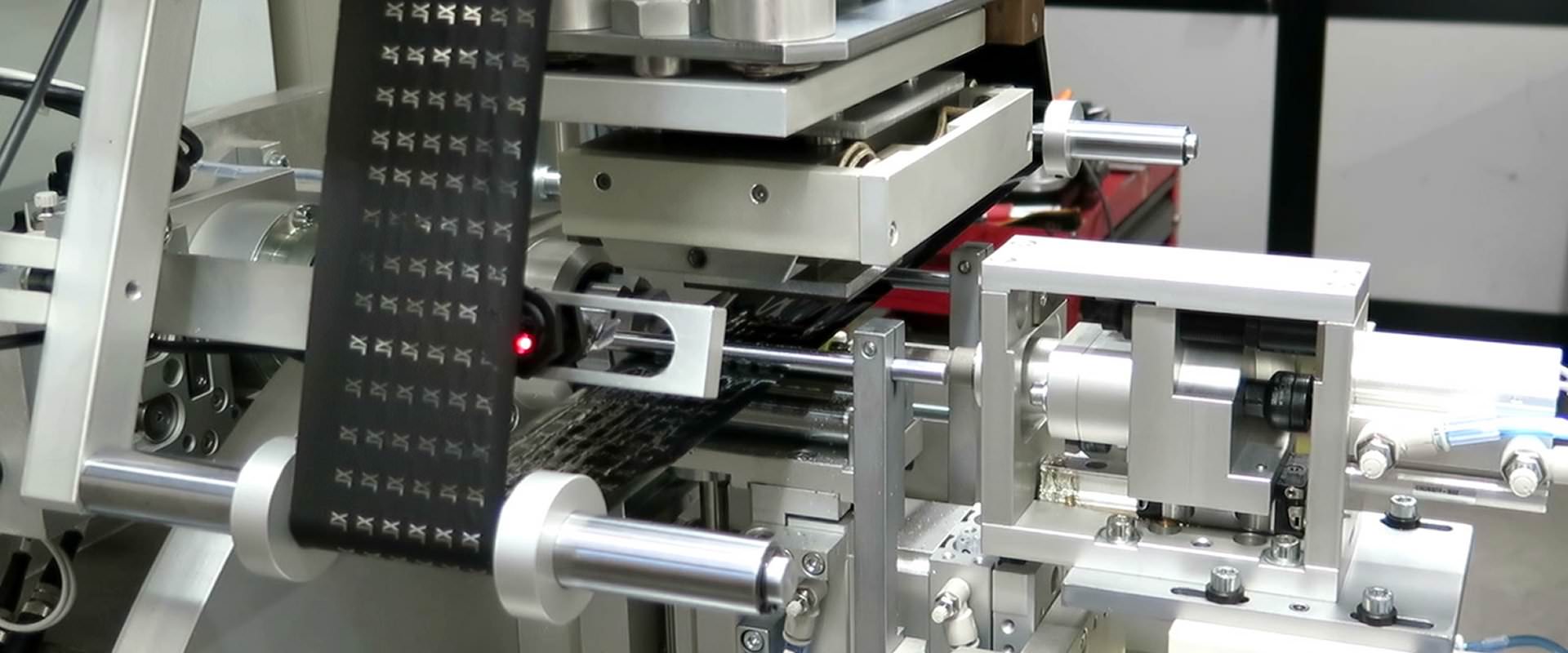

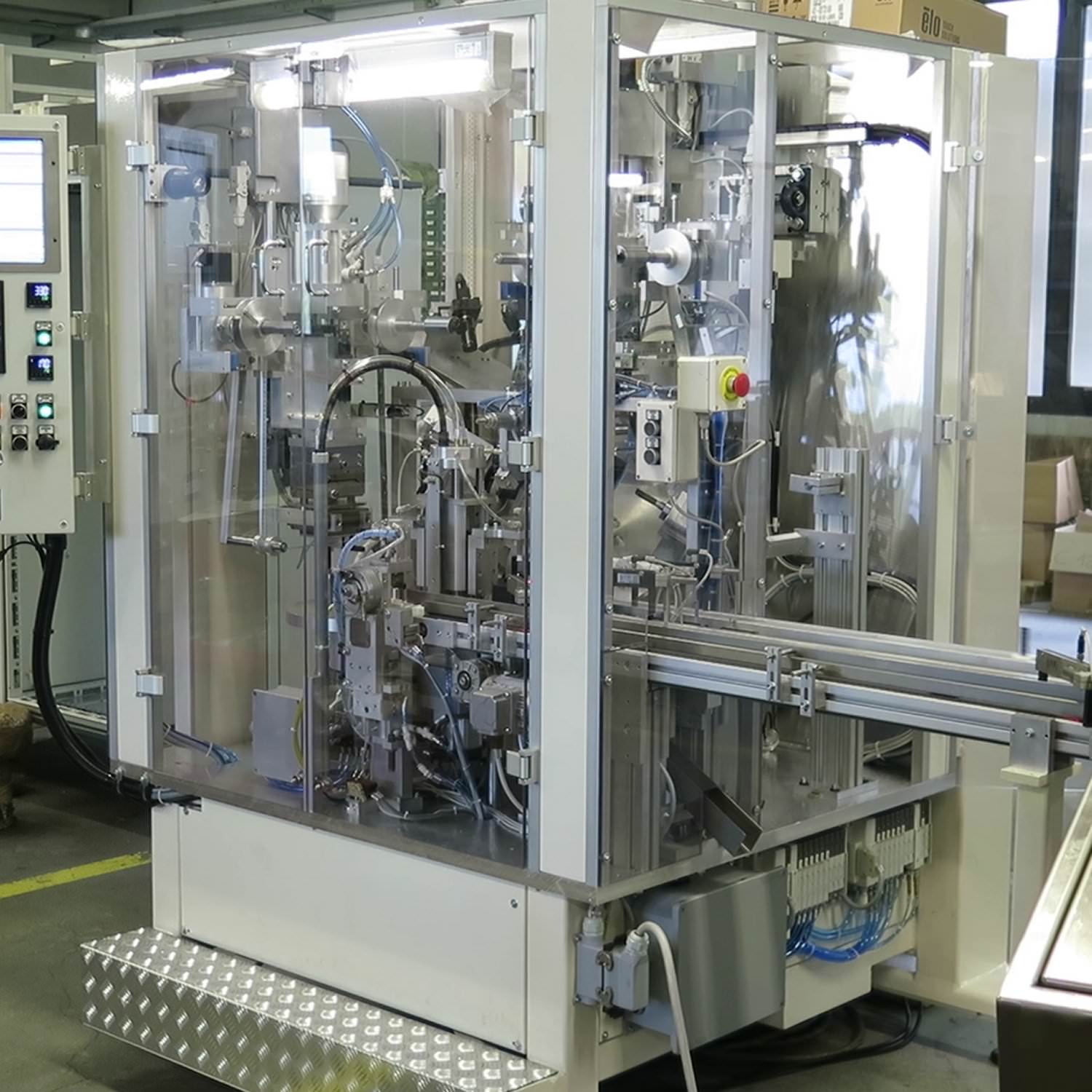

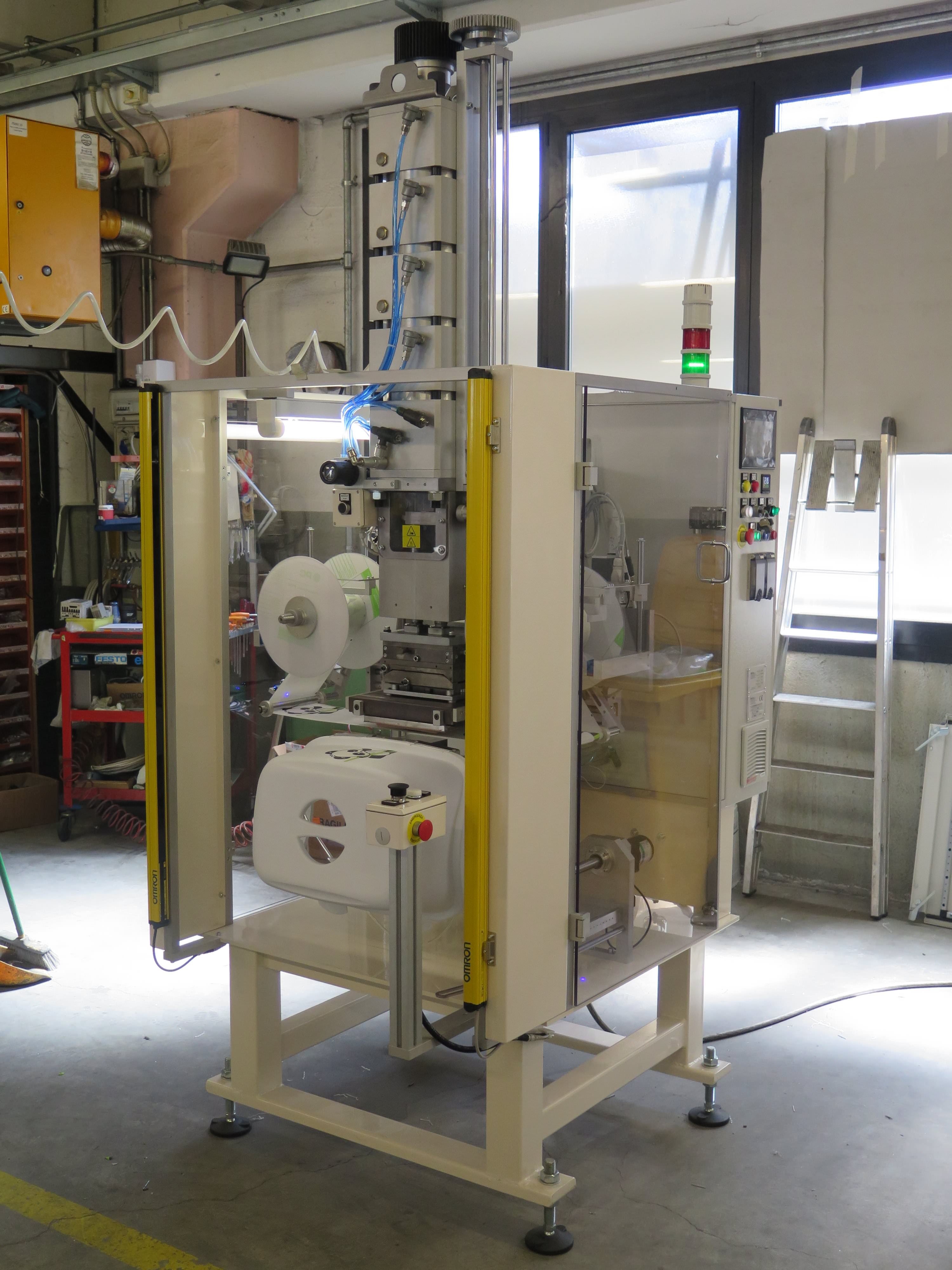

CYLINDRICAL HOT STAMPING MACHINE

DECORATION ON VIALS

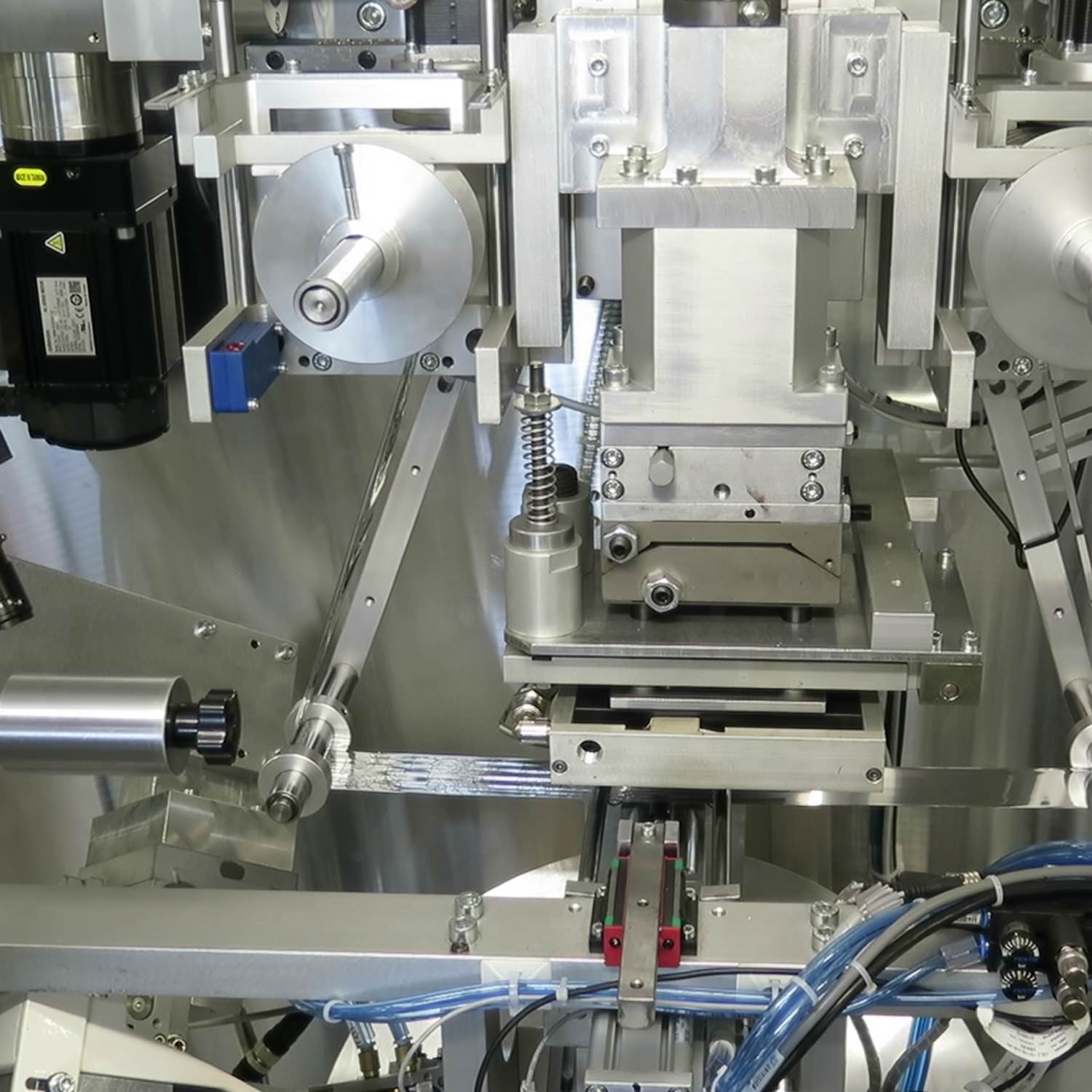

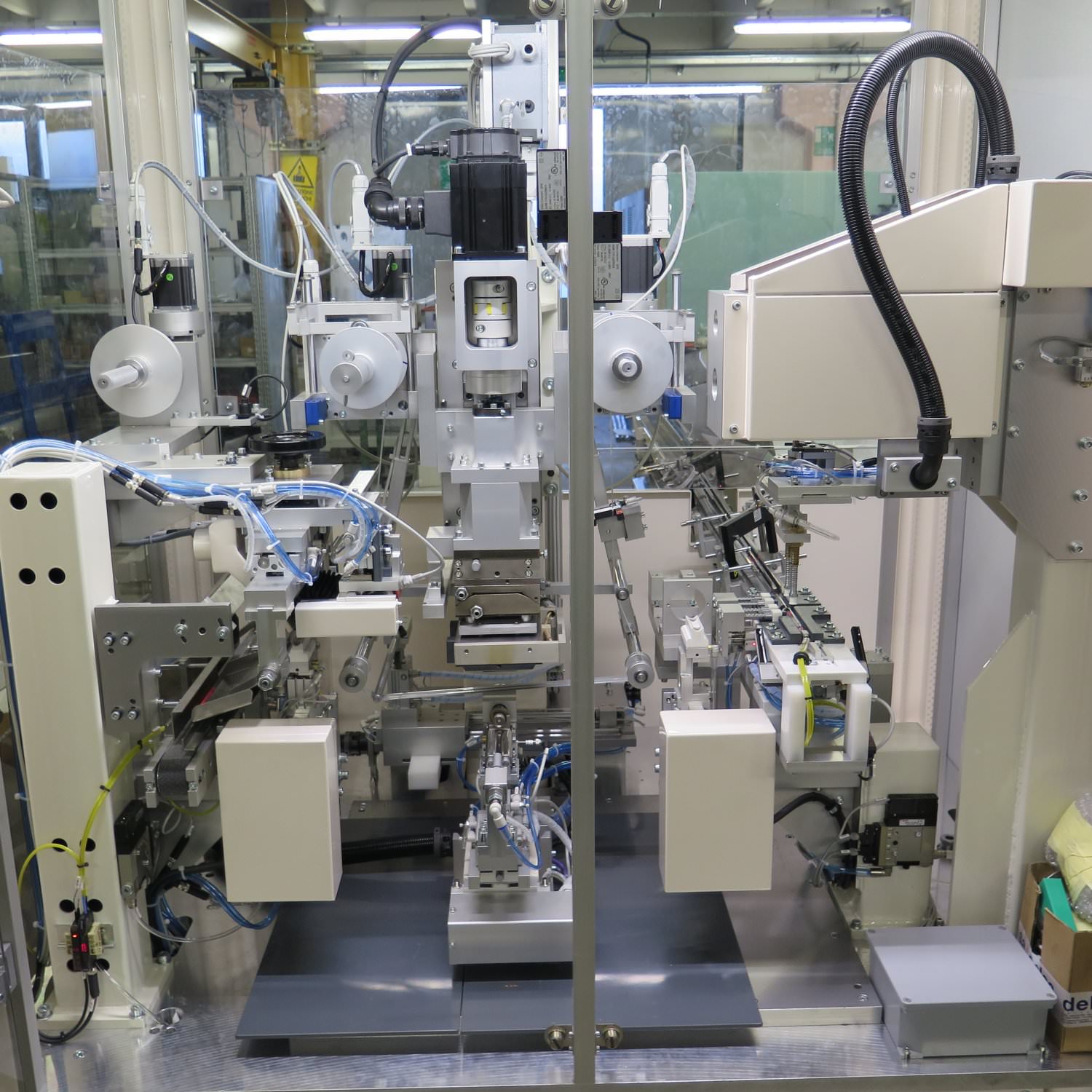

Machine type HS3/PR+C

• electric hot stamping machine for vials

• electric head for cylindrical stamping

• 4 axis automated table-top for part handling during conical, elliptical, convex and cylindrical vials stamping

• possibility of stamping vials with a diameter from 10 to 30 mm, length from 50 to 120 mm

• max.cadence: 2400 items p/h