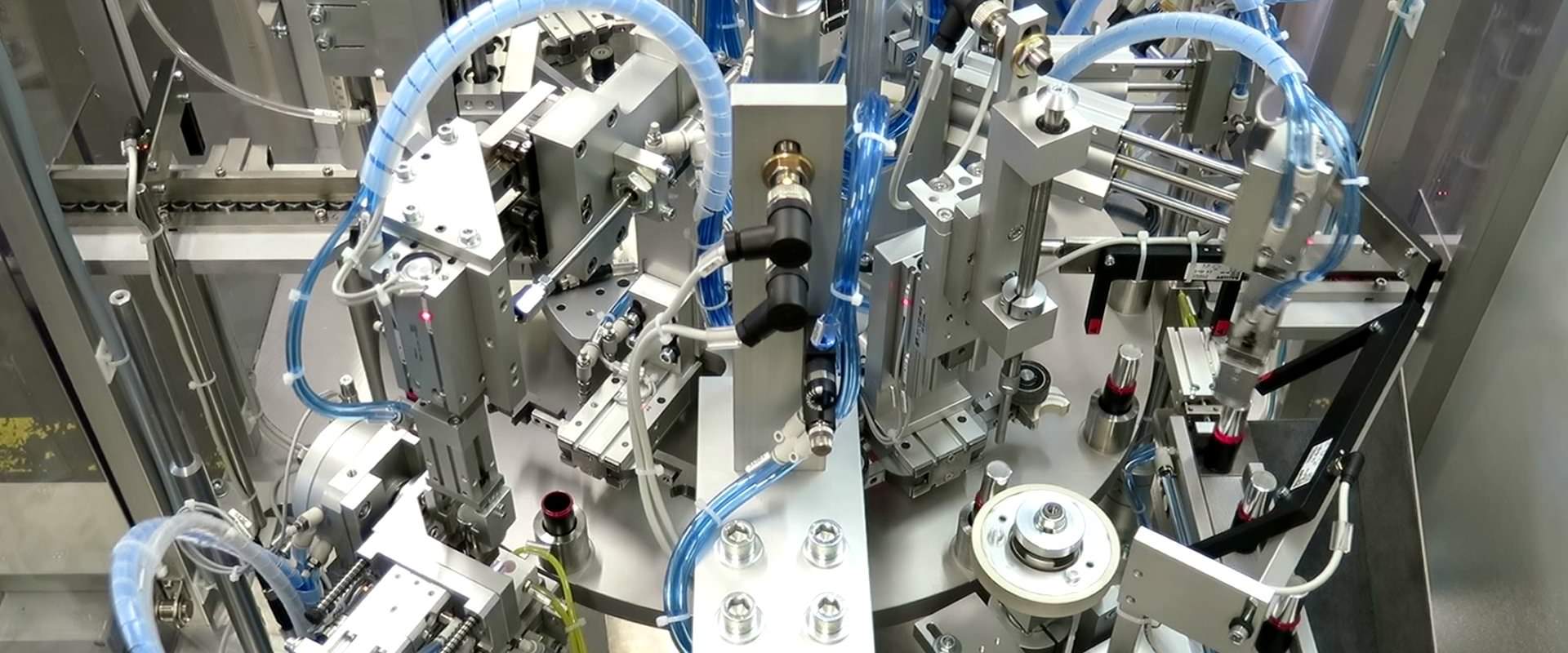

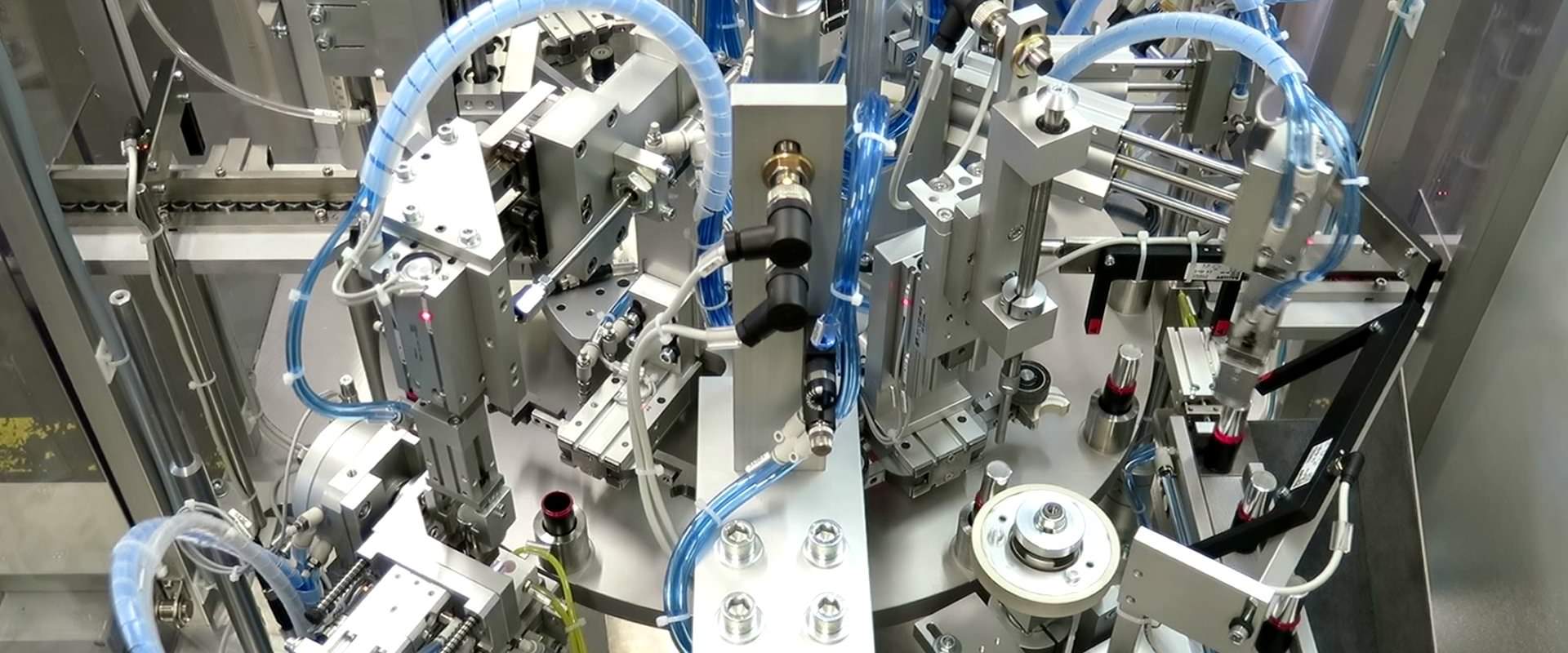

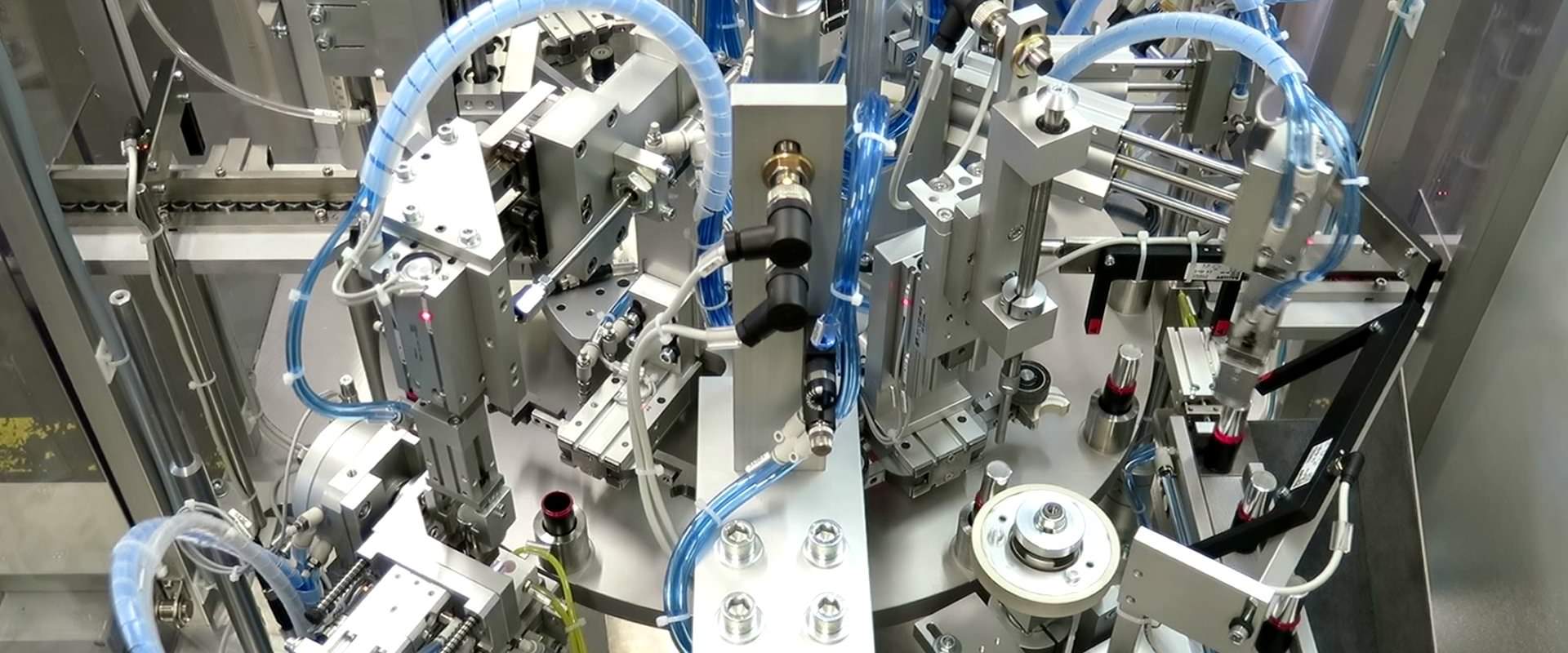

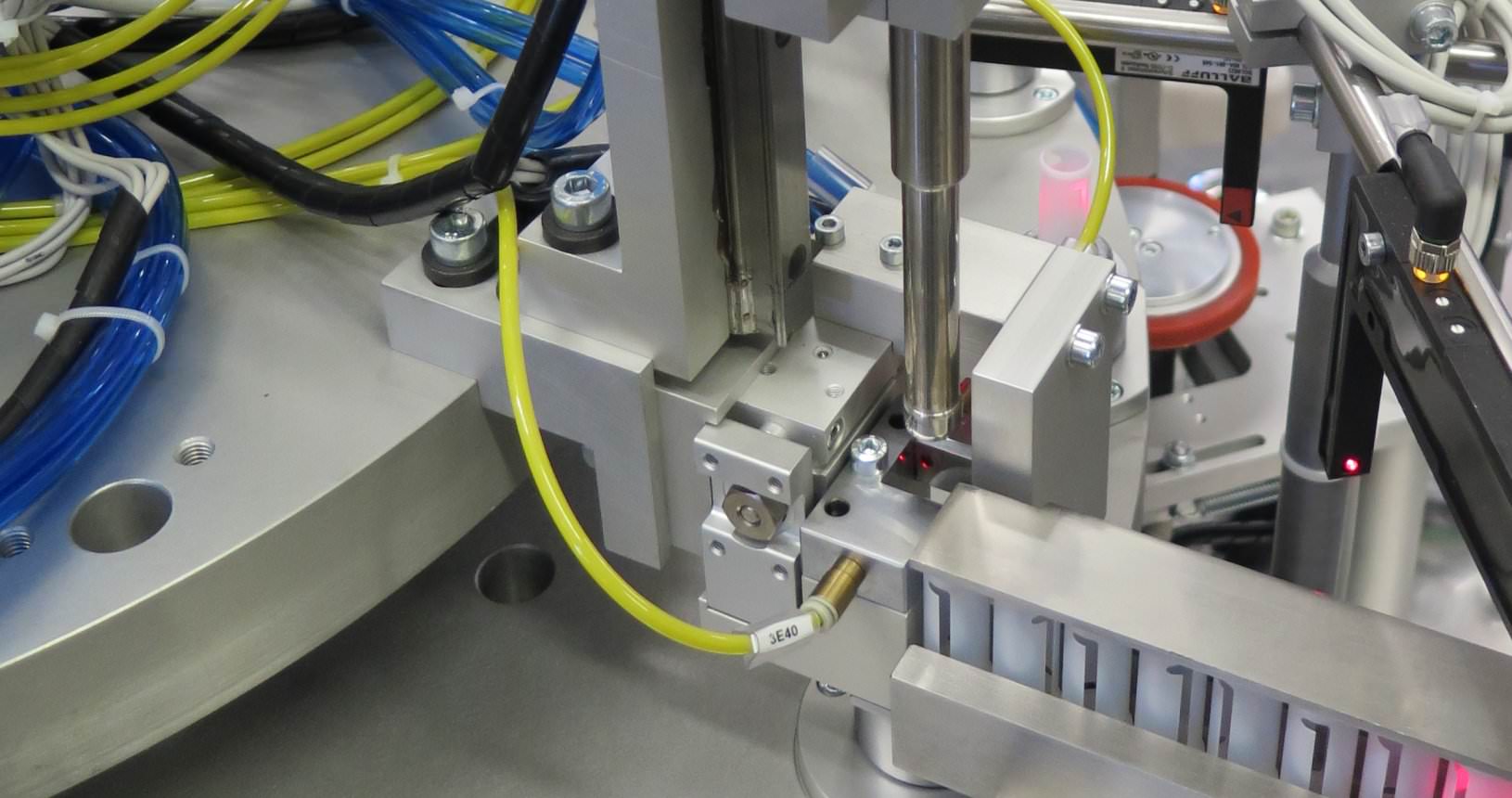

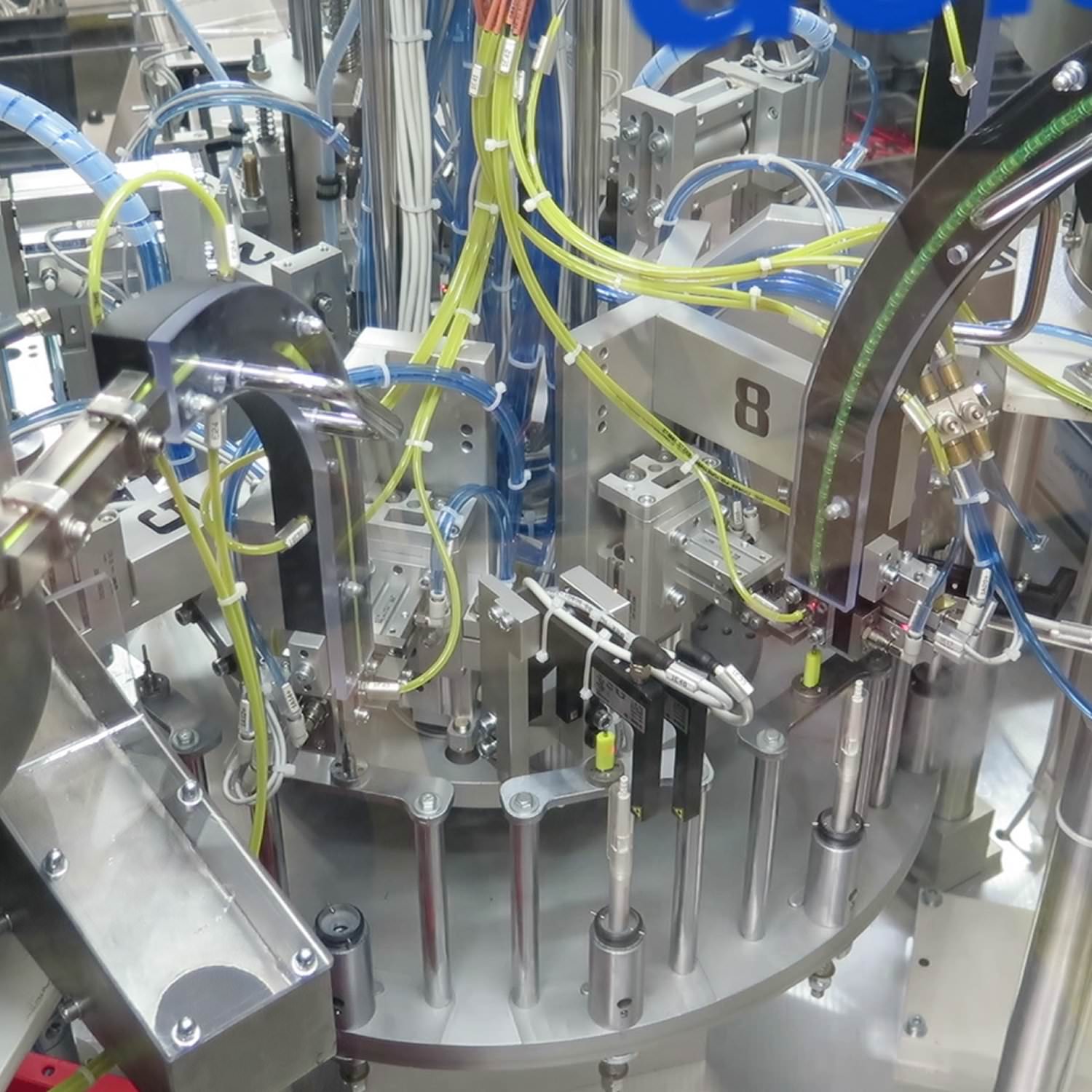

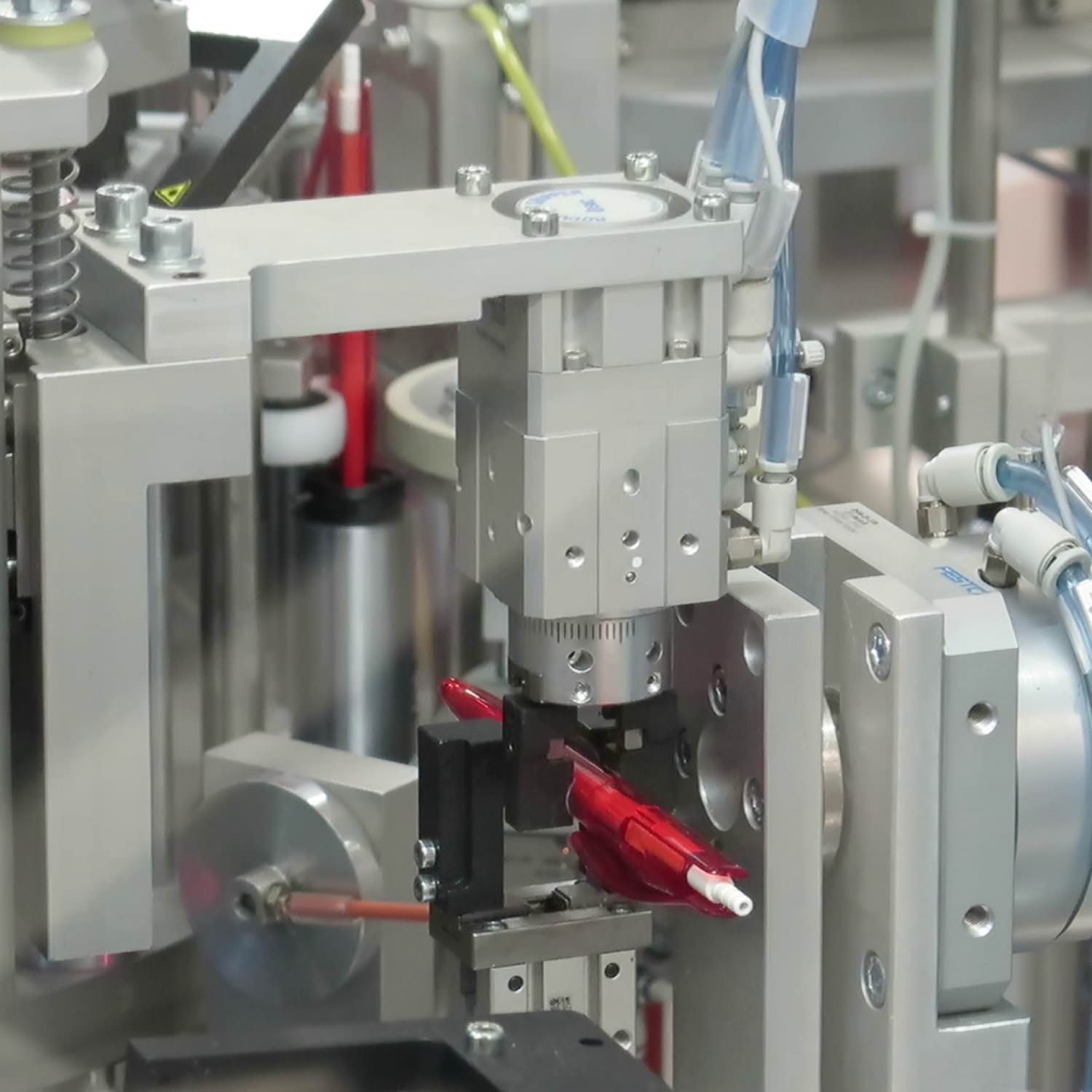

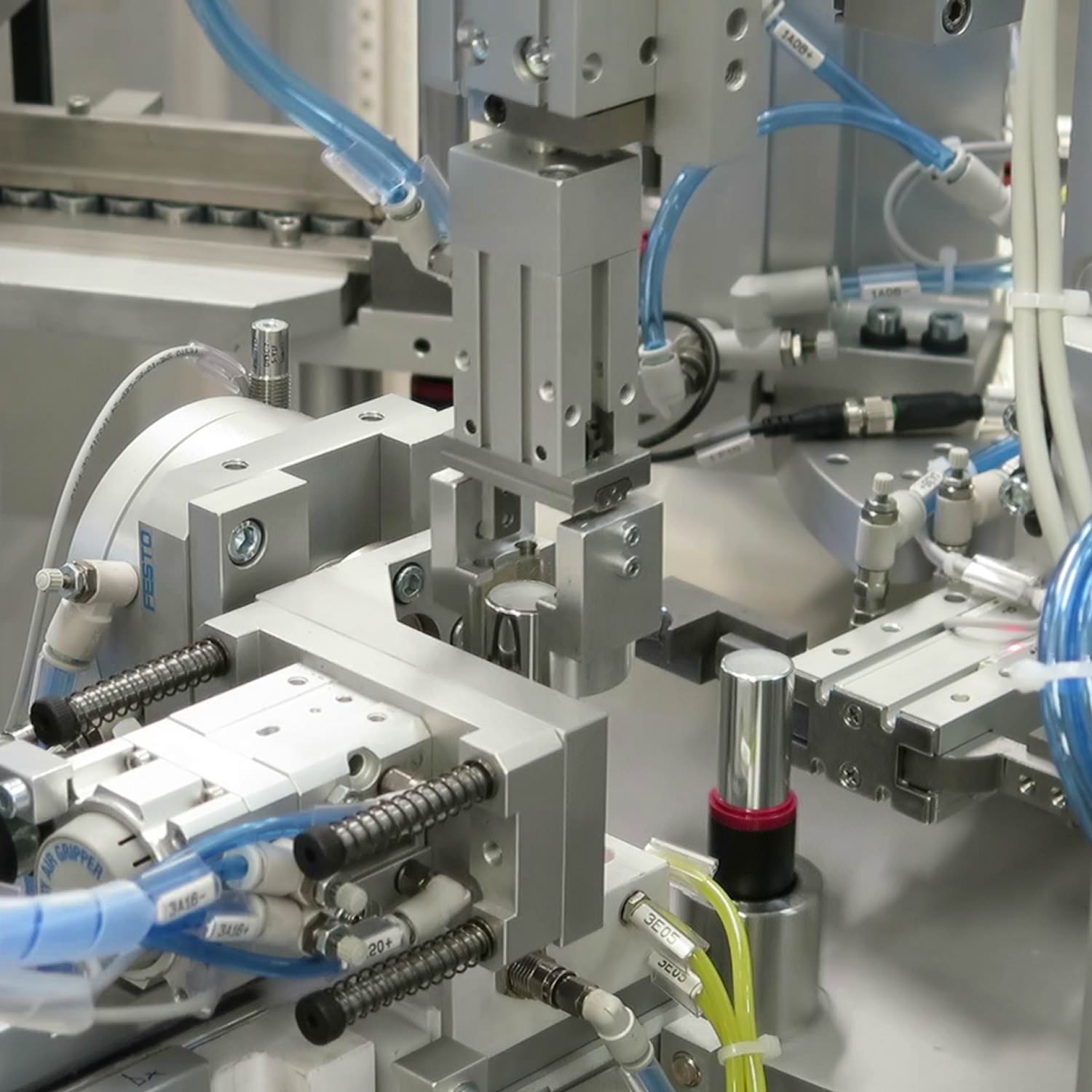

PEN ASSEMBLY MACHINE

Machine type T10/24-DS6+DS8

• pen assembly machine with mechanical rotating table with 24 stations

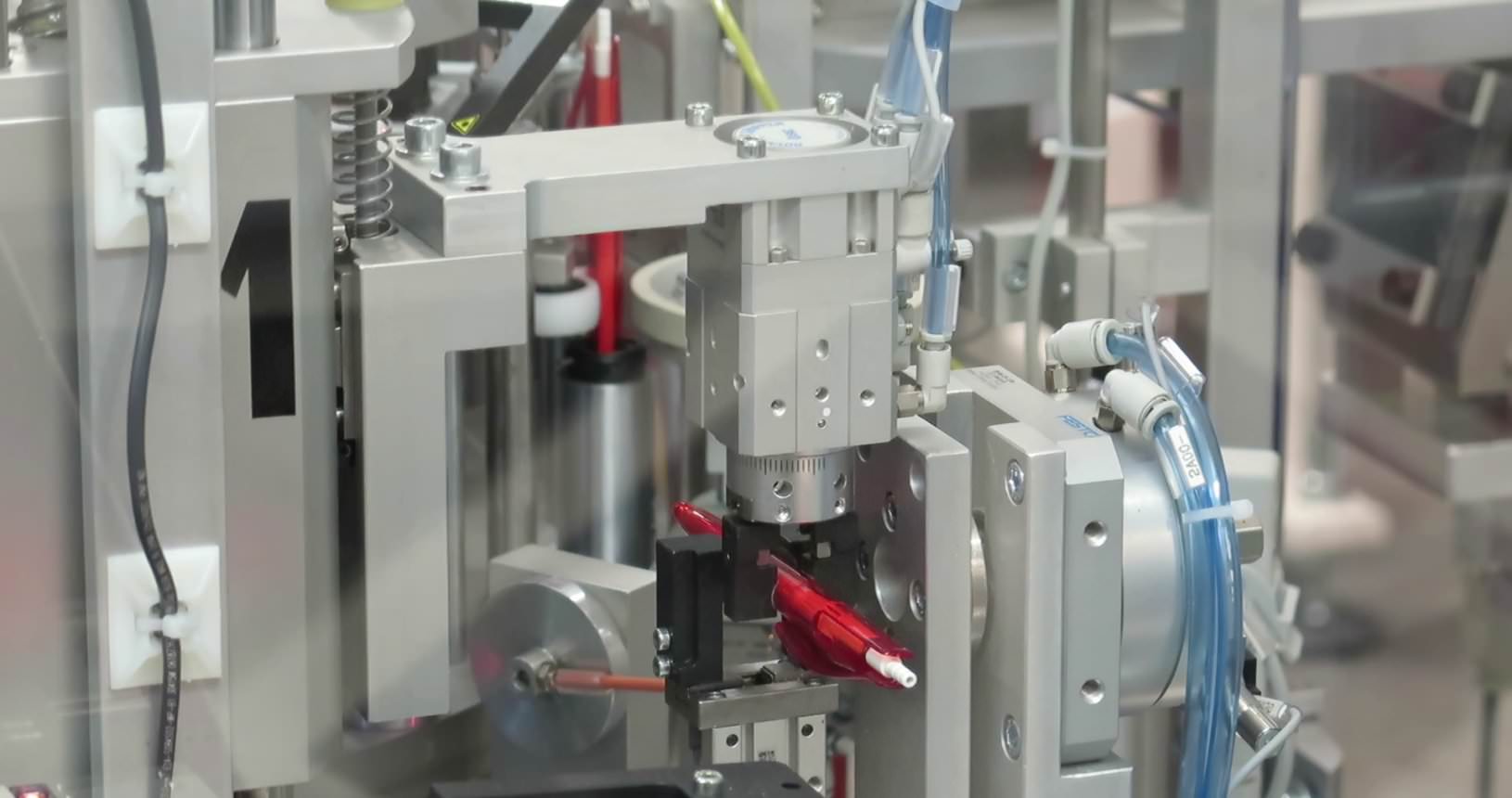

• pivot unit vibratory feeder, clip, push button / subbuttons, spring, rotor

• processing on 2 lines: external line for loading and controlling components; internal line for preassembled control and unloading of the finished item

• cadence: 3000 pieces p/h